In the ever-evolving landscape of manufacturing, injection molding stands as a stalwart pillar of innovation and efficiency. This revolutionary process has reshaped industries, transforming raw materials into intricate parts and products with unparalleled precision and speed. In this article, we delve into the fascinating world of injection molding, exploring its myriad applications, technological advancements, and the profound impact it has on shaping tomorrow’s possibilities.

Unveiling the Process

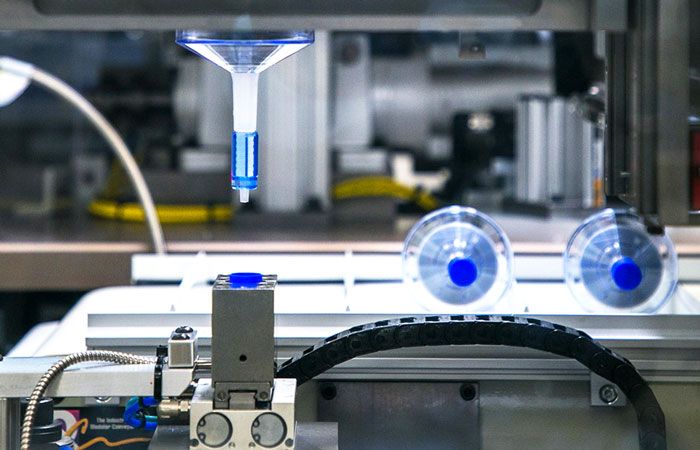

At its core, injection molding is a marvel of engineering ingenuity, capable of producing complex components with remarkable efficiency. The process begins with the melting of thermoplastic or thermosetting materials, which are then injected into a mold cavity under high pressure. Once cooled and solidified, the mold opens, revealing a perfectly formed product ready for use. From automotive components to consumer electronics, injection molding has become the go-to method for manufacturing a vast array of products with unparalleled precision and consistency.

Revolutionizing Industries

The versatility of injection molding knows no bounds, revolutionizing industries and opening doors to new possibilities. In the automotive sector, injection-molded parts have replaced traditional metal components, reducing weight, improving fuel efficiency, and enhancing overall performance. In the medical field, intricate devices and implants are manufactured with precision, improving patient outcomes and quality of life. From household appliances to aerospace components, injection molding has become synonymous with innovation, driving progress and pushing boundaries in every sector.

Technological Advancements

As technology continues to evolve, so too does the world of injection molding. Cutting-edge innovations such as 3D printing and computer-aided design (CAD) have revolutionized the design and production process, allowing for greater customization, faster turnaround times, and reduced waste. Advanced materials and additives have expanded the possibilities even further, enabling manufacturers to create products with enhanced durability, strength, and functionality. With each technological leap, injection molding pushes the boundaries of what’s possible, paving the way for a future defined by limitless potential.

Sustainability and Efficiency

In an era marked by growing environmental awareness, injection molding has emerged as a champion of sustainability and efficiency. By optimizing material usage, minimizing waste, and streamlining production processes, manufacturers can reduce their carbon footprint and conserve valuable resources. Recycled materials and bioplastics offer further opportunities for eco-friendly manufacturing, ensuring that injection molding remains at the forefront of sustainable innovation for years to come.

In conclusion, injection molding stands as a testament to human ingenuity and innovation, shaping the world around us in profound ways. From revolutionizing industries to driving technological advancements, its impact reverberates across every aspect of modern life. As we look to the future, the possibilities are boundless, with injection molding leading the way towards a world defined by creativity, efficiency, and sustainable progress. With each mold that opens, we glimpse a glimpse of tomorrow—a world shaped by the endless possibilities of injection molding.