In the dynamic world of manufacturing, innovation continually drives progress, enhancing efficiency, functionality, and aesthetic appeal of products. Among these innovations, plastic over-molding stands out as a versatile and transformative process, offering myriad benefits across various industries. This article explores the fundamentals of plastic over-molding, its applications, advantages, and its significant impact on modern manufacturing.

What is Plastic Over-molding?

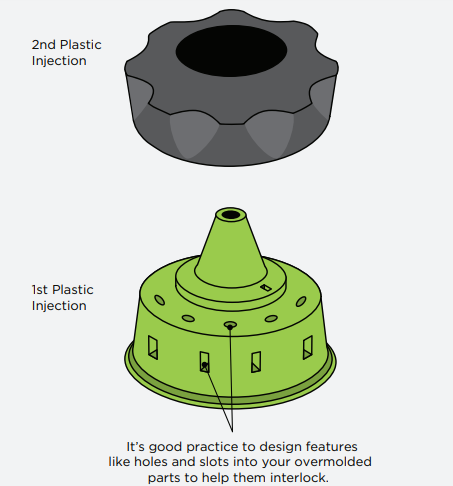

Plastic over-molding is a multi-step injection molding process that involves molding a layer of plastic over a pre-existing component or substrate. This substrate can be another plastic part, metal, or other materials. The primary objective is to combine different materials to create a single, integrated component with enhanced properties, improved functionality, and aesthetic appeal.

The Over-molding Process

The over-molding process typically involves the following steps:

- Preparation of the Substrate: The initial step is the preparation of the substrate, which could be a plastic or metal component. This substrate is often manufactured separately using conventional molding or machining techniques.

- Placement in the Mold: The prepared substrate is then placed into a specially designed mold that accommodates both the substrate and the over-mold material.

- Injection Molding: The over-mold material, usually a thermoplastic or elastomer, is injected into the mold, encapsulating the substrate. This process can be done using various injection molding techniques, depending on the material and design requirements.

- Cooling and Ejection: Once the over-mold material has solidified and cooled, the finished product is ejected from the mold. The result is a cohesive part with multiple material layers seamlessly bonded together.

Applications of Plastic Over-molding

Plastic over-molding is utilized in a wide range of industries, thanks to its ability to enhance product performance and aesthetics. Some notable applications include:

- Automotive Industry: Over-molding is used to produce components such as steering wheels, gear knobs, and handles. These parts benefit from improved grip, durability, and a visually appealing finish.

- Consumer Electronics: Over-molding provides electronic devices with ergonomic designs, enhanced shock resistance, and better insulation. Common examples include mobile phone cases, remote controls, and headphones.

- Medical Devices: In the medical field, over-molding is employed to create devices with better grip, comfort, and biocompatibility. This includes items like surgical instruments, syringes, and wearable medical devices.

- Tooling and Hardware: Over-molding is used to manufacture tools with comfortable, non-slip handles and increased durability. Examples include screwdrivers, pliers, and power tool grips.

Advantages of Plastic Over-molding

Plastic over-molding offers several advantages that make it a preferred choice in many manufacturing processes:

- Enhanced Functionality: By combining multiple materials, over-molding can enhance the functionality of a product. For instance, adding a soft-touch over-mold can improve grip and comfort.

- Improved Aesthetics: Over-molding allows for the incorporation of different colors and textures, resulting in visually appealing products with a premium feel.

- Cost Efficiency: Over-molding can reduce assembly costs by eliminating the need for additional parts and adhesive bonding processes.

- Durability and Strength: The bonding of different materials can result in components with superior mechanical properties, including increased strength and resistance to wear and tear.

- Design Flexibility: Over-molding offers immense design flexibility, enabling manufacturers to create complex and intricate designs that meet specific application requirements.

Plastic over-molding has revolutionized manufacturing by providing a versatile and efficient method to enhance product functionality, aesthetics, and durability. Its applications span across various industries, making it a critical process in modern manufacturing. As technology continues to advance, the potential for over-molding to drive innovation and improve product performance is boundless. Embracing this technique allows manufacturers to stay competitive, meet customer demands, and push the boundaries of what is possible in product design and functionality.