Embarking on the journey of bringing an invention to life requires more than just a groundbreaking idea. For inventors, the prototyping process is a critical step that transforms concepts into tangible, testable models. Navigating this phase effectively can significantly impact the success of the invention. In this guide, we’ll explore key aspects of the prototyping process and offer valuable insights for inventors seeking to bring their creations to fruition.

- Define Your Objectives:

Before diving into prototyping, clearly define the objectives you aim to achieve. Whether it’s validating the concept, testing functionality, or showcasing your invention to potential investors, a well-defined purpose will guide the entire process. - Sketch and Conceptualize:

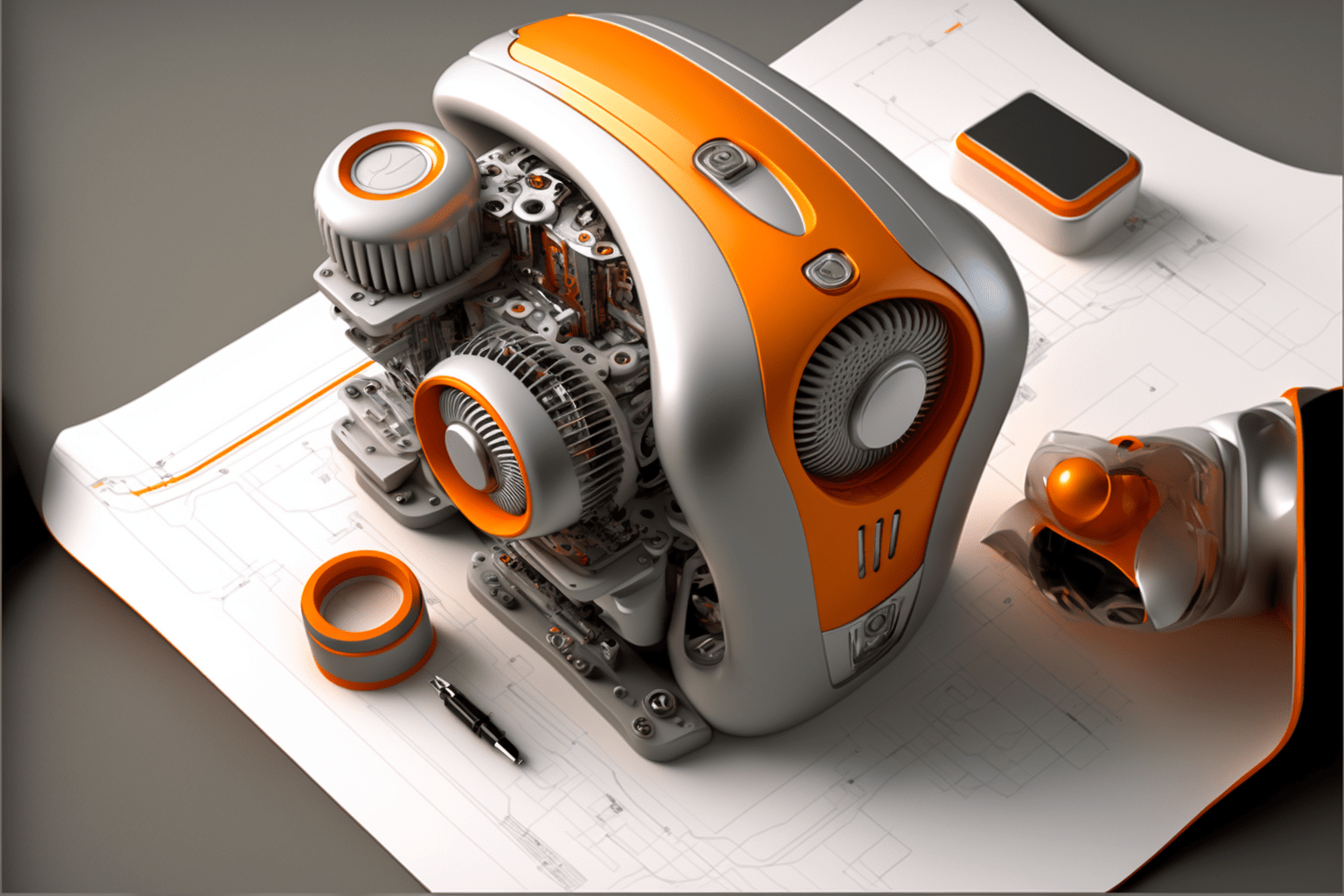

Begin with sketches and conceptual drawings to visualize your invention. These early-stage visualizations serve as a foundation for the prototype, helping you communicate your ideas and make initial design decisions. - Select the Right Prototyping Method:

There are various prototyping methods available, ranging from simple paper prototypes to sophisticated 3D printing. Consider the complexity of your invention, budget constraints, and the level of detail required to determine the most suitable prototyping method for your needs. - Create a Proof of Concept:

Develop a basic prototype to demonstrate the core functionality of your invention. This proof of concept allows you to test key features, identify potential challenges, and refine your design before investing further resources. - Iterate and Refine:

Prototyping is an iterative process. Expect to go through multiple iterations, making improvements based on feedback and testing results. Embrace the opportunity to refine your invention, enhancing its performance, usability, and overall design. - Engage with Prototyping Tools:

Leverage prototyping tools that align with your skill set and project requirements. Software tools, such as CAD (Computer-Aided Design) programs, can facilitate the creation of detailed virtual prototypes, while physical prototyping tools aid in constructing tangible models. - Consider Material Selection:

The choice of materials for your prototype is crucial. Consider factors like durability, flexibility, and cost when selecting materials. Keep in mind that the goal is to create a representative model that captures the essence of your invention. - Test and Gather Feedback:

Rigorous testing is essential to ensure your prototype performs as intended. Seek feedback from potential users, industry experts, and mentors. Use this feedback to make informed decisions and refine your prototype further. - Prepare for Scaling:

As your prototype nears completion, start thinking about the scalability of your invention. Consider manufacturing processes, materials for mass production, and potential challenges that may arise during the scaling phase. - Document the Process:

Throughout the prototyping process, document every step, decision, and modification. This documentation serves as a valuable resource for future reference, troubleshooting, and potential patent applications.

Conclusion:

Navigating the prototyping process is a dynamic and challenging endeavor for inventors. By approaching it with a strategic mindset, embracing iteration, and leveraging the right tools, you can transform your inventive ideas into tangible prototypes. Remember that each step brings you closer to realizing your vision and taking your invention to the next level.

Reach out to us today and learn about our prototype engineering services and capabilities that meet your product needs.