In the world of modern manufacturing, laser cutting has emerged as a game-changing technology that revolutionizes the way we design and produce a wide range of products. From intricate automotive parts to delicate medical devices, laser cutting has become an indispensable tool for precision manufacturing. This article explores the fascinating world of laser cutting, its applications, benefits, and its impact on the manufacturing industry.

What is Laser Cutting?

Laser cutting is a precise and versatile manufacturing process that utilizes a highly focused laser beam to cut, engrave, or etch various materials with exceptional accuracy. The laser beam is generated by amplifying light through stimulated emission, producing a concentrated beam of high-energy photons. This intense beam is then directed onto the material, heating it to the point of vaporization or melting, resulting in a clean and precise cut.

Applications of Laser Cutting

The versatility of laser cutting technology makes it suitable for a diverse range of applications across industries. Here are some notable areas where laser cutting excels:

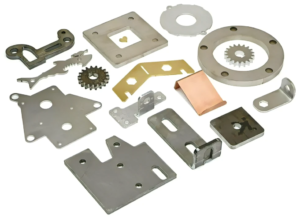

- Industrial Manufacturing: Laser cutting finds extensive use in industrial manufacturing processes. It can cut various materials such as metal, plastic, wood, fabric, glass, and ceramics. This enables the production of intricate components for machinery, automobiles, aircraft, and electronics.

- Prototyping and Rapid Manufacturing: Laser cutting facilitates rapid prototyping and short production runs by quickly and accurately cutting complex shapes. This makes it an ideal solution for product development and custom manufacturing.

- Art and Architecture: Artists, designers, and architects have embraced laser cutting as a means to create intricate patterns, sculptures, and architectural models. The precision and flexibility of laser cutting enable the realization of intricate designs that were once impractical to achieve by traditional means.

- Medical Devices: Laser cutting plays a crucial role in the production of medical devices such as stents, catheters, and surgical instruments. The precise nature of laser cutting ensures the fabrication of intricate components with minimal heat-affected zones, reducing the risk of damage to delicate materials.

Benefits of Laser Cutting

The increasing popularity of laser cutting can be attributed to its numerous benefits, which include:

- Precision and Accuracy: Laser cutting offers unparalleled precision, allowing for intricate designs and tight tolerances. It produces clean, smooth edges, reducing the need for post-processing and minimizing material waste.

- Versatility: Laser cutting is highly versatile and compatible with various materials, including metals, plastics, and organic substances. This versatility enables manufacturers to work with a wide range of materials and create complex designs.

- Speed and Efficiency: Laser cutting is a fast and efficient process, enabling high-speed production and quick turnaround times. Its non-contact nature eliminates the need for tool changes, reducing downtime and increasing productivity.

- Cost-Effectiveness: Although laser cutting technology requires an initial investment, it offers long-term cost savings. The elimination of tooling costs and reduced material waste contribute to overall cost-effectiveness.

Impact on the Manufacturing Industry

Laser cutting has had a transformative impact on the manufacturing industry, driving advancements in product design, quality, and production efficiency. Some notable contributions include:

- Enhanced Design Freedom: Laser cutting enables designers to push the boundaries of traditional manufacturing constraints, resulting in the creation of more innovative and complex products.

- Improved Quality Control: Laser cutting ensures consistent and accurate cuts, reducing errors and defects. This leads to improved quality control and enhanced product reliability.

- Increased Production Efficiency: The speed, precision, and automation capabilities of laser cutting contribute to enhanced production efficiency. Manufacturers can achieve faster production cycles, shorter lead times, and increased throughput.

- Customization and Personalization: Laser cutting allows for easy customization and personalization of products, catering to individual customer preferences. This ability to provide unique and tailored products enhances customer satisfaction and opens up new market opportunities.

Conclusion

Laser cutting has emerged as a transformative technology within the manufacturing industry. Its precision, versatility, and numerous benefits have revolutionized the way products are designed, fabricated, and customized. As laser cutting technology continues to advance, we can expect further breakthroughs and applications across a wide range of industries, leading us into a future where precision manufacturing is the norm.

Reach out to us today and learn about our laser cutting capabilities that meet your product needs.