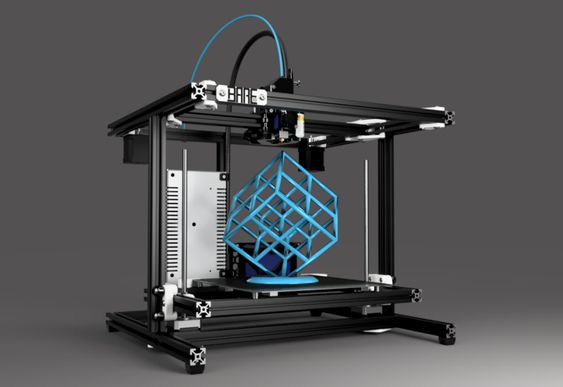

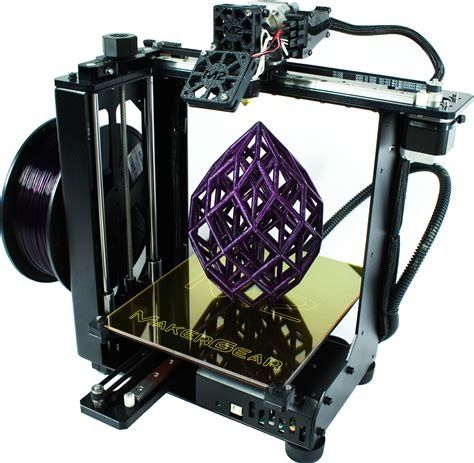

In the production sector, there are few innovations that have garnered as much attention and potential for creativity as additive manufacturing, typically referred to as 3D printing. An idea that was previously perceived as fictional is now an actuality, with uses that extend across various sectors, from aviation to healthcare. Throughout the years, additive manufacturing has seen substantial developments, expanding the limits of what can be achieved and transforming conventional manufacturing methodologies. Let’s explore some of the outstanding progressions in this groundbreaking discipline.

Materials Progression

A major breakthrough in additive manufacturing is the increased range of materials that can be used for printing. While originally restricted to plastics, 3D printing can now incorporate metals, ceramics, composites, and even biological substances. This expanded selection of materials has opened up new opportunities across various sectors, allowing for the fabrication of stronger and longer-lasting components with exact mechanical specifications tailored to particular uses. As an example, aviation businesses are now capable of producing lightweight, yet resilient components utilizing advanced metal alloys, thereby improving fuel efficiency and overall performance.

Multimaterial Printing

In the past, 3D printing typically involved adding one material at a time to build up layers. However, advancements have made it possible to print multiple materials at the same time within a single object. This capability, called multimaterial printing, enables the incorporation of various functions and properties into one component. For instance, a medical device could be printed using both rigid and flexible materials to achieve optimal performance and comfort. Multimaterial printing allows for the creation of intricate geometries and structures that were previously unachievable, fueling innovation in product design and functionality.

Large-Scale Printing

3D printing technology has evolved, overcoming the earlier constraint of smaller sizes. As a result, large-scale additive manufacturing systems have been developed. These systems have the capability to produce objects of significant size. The introduction of these mega-printers has largely impacted various sectors including construction and architecture. They enable the on-site 3D printing of entire buildings and structural components. This innovation has led to a reduction in construction duration and expenses. Additionally, it has facilitated greater flexibility in design and customization. Consequently, the structures that are being produced are more eco-friendly and robust.

Speed and Efficiency

Significant strides have been made in the field of additive manufacturing, particularly in terms of speed and efficiency. In the past, 3D printing could be a time-consuming process, particularly when it came to producing large or intricate objects. However, thanks to advancements in printing methods such as high-speed sintering and continuous liquid interface production, printing speeds have been greatly enhanced without compromising on accuracy and quality. Moreover, enhancements in software algorithms and automation have streamlined the printing process, minimizing material waste and increasing overall efficiency. These improvements have made additive manufacturing a more viable alternative to traditional manufacturing methods, particularly for low-volume, high-complexity production runs.

Integration of AI and Robotics

The fusion of artificial intelligence (AI) with robotics is set to further innovate additive manufacturing. AI algorithms have the capability to study design requisites, perfect shapes, and foresee potential problems, which results in more proficient and dependable printing operations. Robotics platforms outfitted with state-of-the-art sensors and motors allow for mechanized object manipulation, post-processing, and quality assurance, simplifying the entire production series. This amalgamation of AI and robotics not only quickens creativity but also boosts the expansiveness and availability of additive manufacturing technology.

Additive manufacturing has made significant strides from being a niche technology to becoming a prominent process in manufacturing. Notable improvements and innovations have characterized this journey. The changes include the expansion of materials used, the ability to print with multiple materials, large-scale production, faster processes, and the incorporation of AI and robotics. The development of 3D printing technology is continuously progressing swiftly. As these technologies become more mature and prevalent, they have the capacity to disrupt the conventional manufacturing ideas, open up new creative possibilities, and give industries the ability to address intricate issues with unmatched flexibility and efficiency. Additive manufacturing is transforming not just the production process but also the future as a whole.