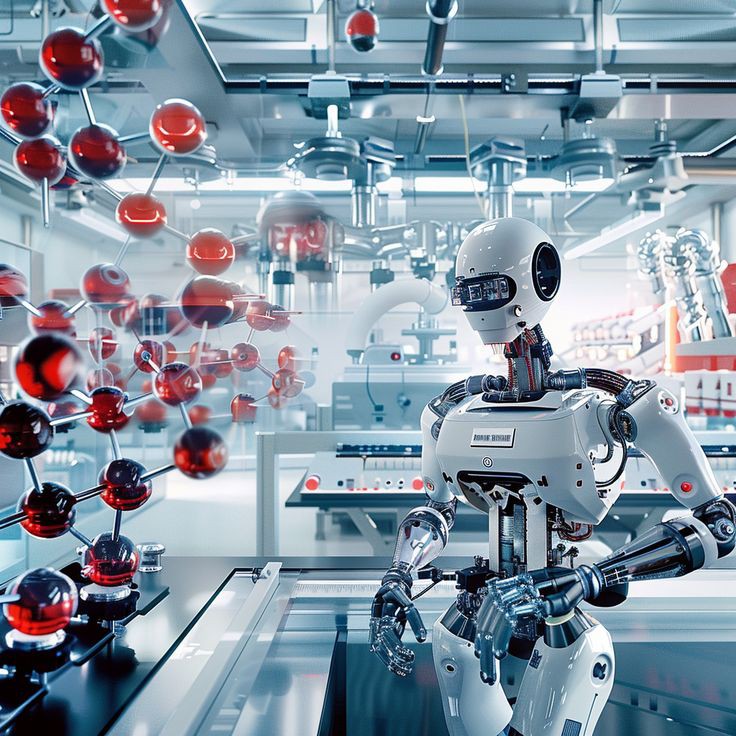

The manufacturing sector is undergoing a profound transformation, largely driven by the integration of advanced robotics. These cutting-edge technologies are not just enhancing production efficiency but are also redefining the landscape of industrial operations.

Advanced robotics brings a new level of precision and consistency to manufacturing processes. Unlike human workers, robots can perform repetitive tasks with a high degree of accuracy and without fatigue. This consistency is crucial in industries where precision is paramount, such as electronics and automotive manufacturing. By minimizing errors and reducing waste, robots help companies maintain high standards of quality and reliability.

Enhanced Workplace Safety

Moreover, robots excel in performing hazardous or strenuous tasks, thereby improving workplace safety. In environments where exposure to toxic substances or heavy machinery is a concern, robots can take on these dangerous roles, protecting human workers from potential harm. This shift not only enhances safety but also allows human employees to focus on more complex and creative aspects of production.

Flexibility and Adaptability

The flexibility of modern robotic systems is another significant advantage. Unlike traditional manufacturing equipment, which is often designed for a specific task, advanced robots can be reprogrammed and retooled for different functions. This adaptability is particularly valuable in an era where consumer demands and market conditions can change rapidly. Manufacturers can quickly adjust their production lines to accommodate new products or design changes, ensuring they remain competitive and responsive to market needs.

Long-Term Cost Savings

In addition to improving efficiency and safety, advanced robotics contributes to cost savings in the long term. While the initial investment in robotic systems can be substantial, the reduction in labor costs, increased productivity, and lower error rates can lead to significant savings over time. As robots become more affordable and accessible, even small and medium-sized enterprises can benefit from their implementation, leveling the playing field in the manufacturing industry.

Future Outlook

Looking ahead, the integration of artificial intelligence and machine learning with advanced robotics promises to push the boundaries even further. These technologies will enable robots to learn from their experiences, make data-driven decisions, and optimize their performance continuously. This evolution will further enhance the efficiency, flexibility, and reliability of manufacturing processes, driving innovation and growth in the industry.

In conclusion, advanced robotics is revolutionizing production lines by enhancing precision, safety, and adaptability. As these technologies continue to evolve and become more integrated with other innovations, they will play an increasingly vital role in shaping the future of manufacturing.