Additive manufacturing, commonly known as 3D printing, has revolutionized the way products are designed, prototyped, and manufactured. One of its most significant applications is in modeling, where 3D printing offers designers and engineers unparalleled flexibility, speed, and precision. In this article, we’ll explore how to effectively use 3D printing in modeling.

Understanding Additive Manufacturing

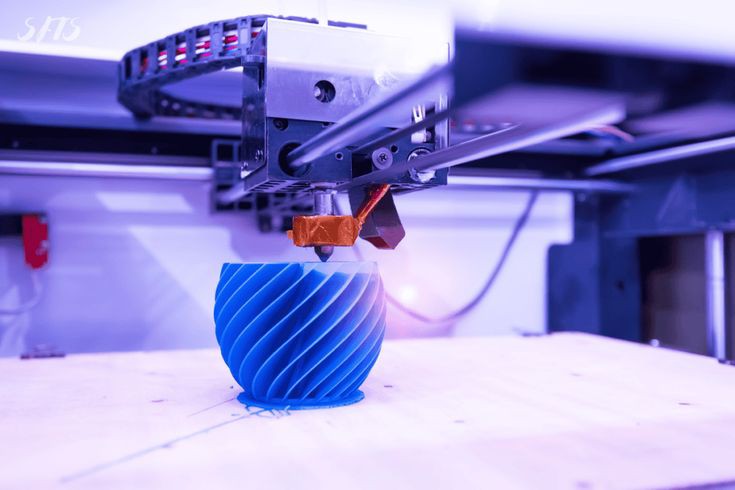

Additive manufacturing builds objects layer by layer using digital 3D models. Unlike traditional subtractive manufacturing methods, which remove material from a solid block, additive manufacturing adds material precisely where needed, resulting in less waste and greater design freedom.

Steps to Use 3D Printing in Modeling

Design Preparation

- Create or Obtain 3D Model: Start with a 3D model of your design. You can create one using CAD (Computer-Aided Design) software or obtain ready-made models from online repositories.

- Optimize for 3D Printing: Ensure your design is optimized for 3D printing by checking for features like overhangs, wall thickness, and support structures. Modify the design if necessary to ensure printability.

Selecting the Right 3D Printing Technology

- Choose the Suitable 3D Printing Process: Select the appropriate 3D printing technology based on your design requirements, material properties, and budget.

- Select Materials: Choose the right material for your model based on factors like strength, flexibility, transparency, and surface finish requirements.

Printing the Model

- Slice the Model: Use slicing software to prepare your 3D model for printing.

- Set Printing Parameters: Adjust printing parameters such as layer height, printing speed, temperature, and support structures based on your material and design requirements.

- Start Printing: Initiate the printing process and monitor the printer to ensure proper adhesion, layer bonding, and quality throughout the print.

Post-Processing

- Remove Supports: Once the printing is complete, remove any support structures used during printing carefully.

- Finish and Clean: Depending on the material and desired finish, post-process the model by sanding, polishing, or applying other finishing techniques.

Evaluate and Iterate

- Inspect the Model: Evaluate the printed model for accuracy, surface finish, and dimensional accuracy compared to the original design.

- Iterate if Necessary: If modifications are needed, make adjustments to the digital model and repeat the printing process until the desired result is achieved.

Benefits of Using 3D Printing in Modeling:

- Rapid Prototyping: 3D printing allows for quick iteration and prototyping of designs, reducing time-to-market.

- Complex Geometries: It enables the creation of complex geometries and intricate designs that are difficult or impossible to achieve with traditional methods.

- Cost-Effective: Compared to traditional prototyping methods, 3D printing can be more cost-effective, especially for low-volume production.

- Customization: Easily create customized models tailored to specific requirements or individual preferences.

Additive manufacturing, particularly 3D printing, offers unmatched advantages in modeling for designers and engineers. By following the steps outlined above and leveraging the benefits of 3D printing technology, you can streamline your modeling process, accelerate innovation, and bring your ideas to life with precision and efficiency. Explore the possibilities of 3D printing and unlock new opportunities in your design projects.